In recent years, 3D printing has emerged as a groundbreaking technology with the potential to revolutionize various sectors. From healthcare to manufacturing, the impact of additive manufacturing is undeniable.

In this article, we will explore the fascinating world of 3D printing, its history, applications, advantages, challenges, and future trends.

What is 3D Printing

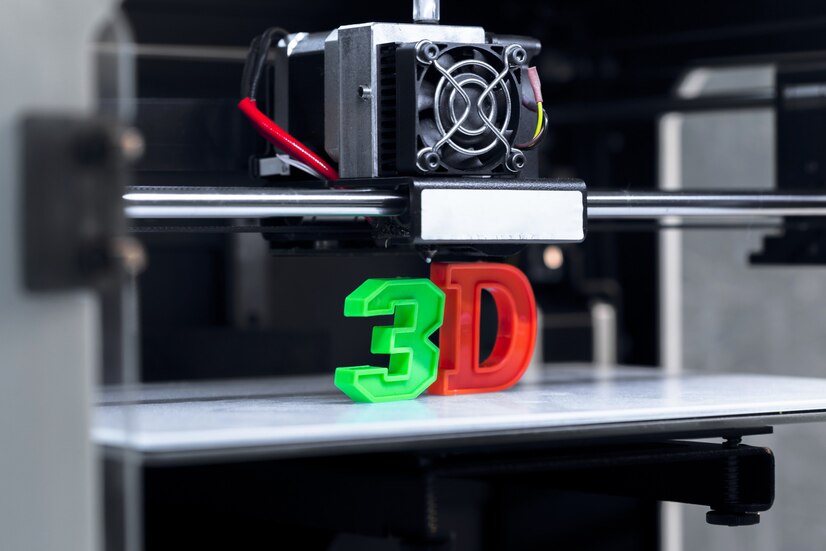

3D printing, also known as additive manufacturing, is a transformative technology that builds objects layer by layer. Unlike traditional manufacturing methods, which subtract material to create a final product, 3D printing adds material precisely where it’s needed. This approach has opened new possibilities across industries, leading to unparalleled innovation.

History of 3D Printing

The roots of 3D printing trace back to the 1980s when the technology first gained recognition. Over the years, it has evolved from basic prototypes to sophisticated creations. Key milestones, such as the development of Stereolithography (SLA) and Fused Deposition Modeling (FDM), have paved the way for the 3D printing landscape we see today.

How 3D Printing Works

Let’s delve into the basics without getting too technical.

Digital Design Creation

Before anything tangible happens, a digital model of the desired object is created using computer-aided design (CAD) software. This digital file serves as the blueprint for the 3D printer.

Slicing the Design

The digital model is sliced into thin horizontal layers using specialized software. These slices act as a guide for the 3D printer, dictating where to deposit material in each layer.

Materials and Printing Technologies

Different 3D printers use various materials, including plastics, metals, and even biological substances. The choice of material depends on the intended use of the final object. Common printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Layer-by-Layer Construction

Once everything is set, the 3D printer starts the magic. It lays down material, layer by layer, following the instructions from the sliced design. This additive process continues until the entire object is formed.

Post-Processing

After the printing is complete, there might be some finishing touches. This could include removing support structures, sanding, or even painting, depending on the desired outcome.

3D printing democratizes manufacturing, allowing for rapid prototyping, customization, and the creation of complex structures that traditional methods struggle with. It’s a game-changer across industries, from healthcare to consumer products.

Applications of 3D Printing

Let’s explore how this innovative technology is making waves in practical ways.

Healthcare Sector

Customized Implants: 3D printing enables the creation of personalized implants tailored to individual patients, improving compatibility and reducing the risk of complications.

Prosthetics: In the U.S., 3D printing is revolutionizing the prosthetics industry, providing cost-effective and customizable solutions for amputees.

Aerospace Industry

Lightweight Components: The aerospace sector benefits from 3D printing’s ability to produce lightweight yet robust components, enhancing fuel efficiency and overall aircraft performance.

Rapid Prototyping: Prototyping new aerospace designs becomes quicker and more cost-effective with 3D printing, allowing for faster innovation cycles.

Automotive Sector

Prototyping and Design: Car manufacturers use 3D printing for rapid prototyping, accelerating the development of new vehicle models and components.

Custom Parts: Enthusiasts and auto companies alike utilize 3D printing to produce custom and hard-to-find parts, reducing dependency on traditional manufacturing.

Consumer Products

Customized Fashion: Designers leverage 3D printing to create personalized fashion accessories and clothing, providing consumers with unique, one-of-a-kind items.

Home Décor: From customized furniture to decorative pieces, 3D printing brings a touch of personalization to home decor products.

The applications of 3D printing extend beyond industrial settings, touching the lives of everyday peoples. From improving healthcare outcomes to empowering individual creativity, 3D printing is reshaping the way we approach design, manufacturing, and even healthcare solutions. Its impact is not just technological but deeply human, ushering in a new era of possibilities.

Advantages of 3D Printing

When it comes to 3D printing, the advantages are as intriguing as the technology itself.

Cost-Effectiveness

Traditional manufacturing often involves hefty setup costs for molds and tooling. 3D printing sidesteps these expenses, making it a cost-effective solution, especially for small-batch production runs. This financial efficiency is a game-changer for businesses aiming to minimize expenses.

Customization and Design Freedom

Designers revel in the freedom this technology provides, unshackled from the constraints of traditional manufacturing methods. This opens the door to unparalleled creativity, producing items that are not just functional but visually striking.

Rapid Prototyping

3D printing accelerates the prototyping phase, allowing businesses to swiftly test and iterate designs. This not only reduces time-to-market but fosters a more agile and responsive approach to product development.

In the world landscape, where innovation and efficiency are highly prized, the advantages of 3D printing align perfectly with the spirit of progress. Businesses, both large and small, can benefit from the cost-effective nature of this technology, while designers find a playground for their creativity. It’s not just a manufacturing method; it’s a catalyst for a more agile, customized, and financially savvy approach to production.

Challenges and Limitations of 3D Printing

While 3D printing has certainly carved a niche for itself in various industries, it’s not without its set of challenges. Let’s dive into the hurdles that this innovative technology faces.

Material Limitations

Despite the expanding repertoire of 3D printing materials, certain industries encounter challenges in finding the perfect match for specific applications. The limitations in material properties can affect the suitability of 3D printing for certain projects.

Speed and Scalability Challenges

While 3D printing is excellent for prototyping and small-scale production, it faces challenges in terms of speed and scalability for large-scale manufacturing. The layer-by-layer approach, while precise, may not be as rapid as traditional manufacturing methods for mass production.

Intellectual Property Concerns

The ease with which objects can be replicated using 3D printing technology raises concerns about intellectual property rights. The potential for unauthorized copying and counterfeiting is a challenge that industries must grapple with in the era of additive manufacturing.

Understanding the challenges of 3D printing is crucial for a nuanced perspective. While the technology offers incredible benefits, acknowledging its limitations is part of a realistic approach. As the industry evolves, addressing these challenges will be instrumental in unlocking the full potential of 3D printing for world businesses and beyond. It’s a journey of innovation that comes with its unique set of roadblocks, calling for continuous refinement and adaptation.

Future Trends in 3D Printing

As we gaze into the horizon of technology, the future of 3D printing holds exciting possibilities. Let’s explore some trends that are likely to shape the landscape of additive manufacturing in the coming years.

Bioprinting

The prospect of printing living tissues and organs, known as bioprinting, is on the rise. This groundbreaking application has the potential to revolutionize healthcare, with implications for organ transplantation and personalized medicine.

Nanoscale Printing

Advancements in nanotechnology are paving the way for nanoscale 3D printing. This could lead to the creation of incredibly small and precise objects, finding applications in fields like electronics, medicine, and materials science.

4D Printing

Building on the concept of 3D printing, 4D printing introduces the dimension of time. Objects printed with this technology can evolve or transform over time in response to environmental stimuli. This dynamic capability opens up avenues in self-assembling structures and adaptive materials.

The future trends in 3D printing showcase a trajectory that extends far beyond the current capabilities. These advancements have the potential to redefine how we approach healthcare, manufacturing, and innovation.

3D Printing in the American Context

The United States has been at the forefront of adopting 3D printing in various industries. From healthcare innovations to aerospace breakthroughs, American companies continue to drive advancements in additive manufacturing.

3D Printing Case Studies

Stratasys: Revolutionizing Prototyping

Stratasys, a pioneer in 3D printing, has transformed product development with its innovative prototyping solutions.

Local Motors: Crowdsourced Vehicle Design

Local Motors has embraced 3D printing to create customizable vehicles, engaging the community in the design process.

The Role of 3D Printing in Sustainable Practices

Eco-friendly Aspects

3D printing minimizes waste by only using the necessary materials, contributing to more sustainable manufacturing practices.

Reducing Waste in Manufacturing

The precision of 3D printing results in minimal material wastage, aligning with global efforts to reduce the environmental impact of production.

3D Printing and the DIY Culture

Influence on the Maker Movement

3D printing has empowered individuals to become creators, fostering a DIY culture where innovation knows no bounds.

Community-driven Projects

Communities around the world collaborate on open-source 3D printing projects, sharing knowledge and driving collective progress.

Common Misconceptions about 3D Printing

Dispelling myths surrounding 3D printing, such as it being limited to plastics or having prohibitive costs, fosters a more accurate understanding of its capabilities.

Personal Experiences with 3D Printing

As a blogger passionate about technology, engaging with 3D printing topics has been a fascinating journey.

Thanks for finding this blog useful for your reading, you can visit TheGreatInfo.com on a regular basis to know more about new technology trends. Have a good day!!